top of page

News & Insights

Explore our articles to discover how our innovative solutions can help you improve efficiency, reduce costs, and protect your valuable equipment.

News & Insights

Explore our articles to discover how our innovative solutions can help you improve efficiency, reduce costs, and protect your valuable equipment.

50GPM Rental VDOPS Gets The Water Out Of Turbine Oil At An Energy Plant In The Midwest

A recent inquiry through our Contact Us page came from a Maintenance Manager at an energy facility in the Midwest United States. The facility was referred to Oil Filtration Systems by a colleague at a sister plant that had previously used our oil filtration rental equipment to resolve similar contamination issues. Identifying Water Contamination in Turbine Oil Systems The maintenance team reported elevated water contamination in turbine oil, caused by a leaking steam seal.

Jan 102 min read

Varnish Contamination In Solar Titan 130 Gas Turbine Generator - powerhouse of a university in NY

Problem: Maintenance personnel at the Power House of a major university in New York noticed discoloration of the Mobil SHC 32 Lube Oil in their Solar Titan 130 Gas Turbine Generator after several years of operation. This prompted them to conduct oil analysis, and the lab results revealed an elevated varnish potential number of MPC 53. If left untreated, operators were worried that varnish would eventually plate out on the metal surfaces within the lube oil system, causing el

Oct 16, 20251 min read

Reliable Solutions - Diesel Fuel Filtration

It is known that Oil Filtration System is an industry leader in Oil Filtration and Purification Equipment Sales, Rentals, and Services. But did you know we also have a full line of diesel fuel filtration and purification equipment as well? Whether you’re looking to rent or purchase fuel coalescer vessels, filtration systems designed specifically for fuels, or even have your fuel polished by the professionals, we have got you covered. Our equipment will ensure that diesel fue

Apr 2, 20251 min read

Keep the Fuel in Your Standby Diesel Generator Absolutely Clean & Dry with a Fuel Polishing System

Left stagnant for long periods of time, the diesel fuel in bulk fuel tanks or belly tanks can become contaminated with moisture due to humidity in the air, and algae can then form at the fuel/air interface. Left unchecked, moisture, algae, fungus, sludge, and other particulate matter will contaminate the fuel, which can then cause problems with start-up and operation of the diesel engine when it is needed most - during an emergency! A Fuel Polishing System will recirculate

Mar 11, 20252 min read

Ensuring Clean, Contaminant-Free Fuel Systems with Professional Flushing Services

Maintaining clean, moisture-free piping and supply lines in critical fuel systems is essential for reliable performance.

Feb 10, 20251 min read

Keep Your Turbine Oil Clean, Dry, and Varnish Free – Here’s How

They say problems come in threes, and when it comes to your turbine or compressor lube oil reservoir, those three troublemakers are water, particulate, and varnish contamination. Fortunately, Oil Filtration Systems has an all-in-one solution that can help to remove all these contaminants. Our advanced purification technology is also fully compatible with Fyrquel, ECOSafe, and other EHC fluids, helping to reduce the Total Acid Number (TAN) in these oils (on top of water, parti

Feb 6, 20251 min read

Fuel Cleanliness Tips - Filtering New Oil & Kidney-Loop Filtration

This week's #FuelCleanlinessTip is filtering incoming fuel upon delivery and installing kidney-loop filtration systems on bulk fuel tanks. Fuel delivered in tankers can be notoriously dirty (ISO 21/19/17) Make sure that new fuel is filtered on its way into the bulk tank Use high-efficiency 2.5 micron filters rated Beta>1000 per ISO 16889 Use coalescer/separator elements to effectively remove moisture Run continuously or on a timer for periodic filtration To ensure that the

Oct 24, 20241 min read

Effectively Remove Varnish From Your Lube Oil With Varnish Removal Systems (VRS)

WHY BE CONCERNED ABOUT VARNISH? Lubricant varnish has become a significant maintenance problem in many critical hydraulic and lubrication oil applications, such as gas turbines, compressors, and hydraulic presses. Turbine oil varnish has been a particularly high profile issue over the last decade. A very small amount of varnish that settles in a susceptible zone, such as a fuel control or IGV valve, can prevent the system from starting properly, resulting in a fail-to-start c

Oct 8, 20242 min read

Properly Remove Varnish From Your Lube Oil With Varnish Removal Systems (VRS)

DID YOU KNOW? Lubricant varnish has become a significant maintenance problem in many critical hydraulic and lubrication oil applications. A Varnish Removal System (VRS) will enable you to effectively remove both soluble and suspended varnish from your lube oil, improving overall equipment reliability and saving you money. The VRS by Oil Filtration Systems utilizes a combination of the two leading technologies for varnish mitigation (granular adsorbent media and depth media fi

Sep 24, 20241 min read

High Velocity Oil Flushing Contamination Control / Oil & Fuel Purification Services

Maintenance Managers and Reliability Engineers around the world know how important it is to keep the oil and piping in their critical rotating equipment absolutely clean and dry. This applies to pre-commissioning of new equipment as well as maintenance of existing equipment, and with this purpose in mind, Oil Filtration Systems® provides a wide range of customized high velocity oil flushing, contamination control, and oil & fuel purification services. Typical Flushing Servic

Sep 10, 20241 min read

Your Number One Lube Oil Problem – Moisture

An amazing and very damaging event can occur when water is present in the bearing load zone. The effect produces super heated steam which creates a mini explosion inside the oil, similar to micro-dieseling, that will damage the oil & work harden, fatigue and crack the bearing surfaces. If moisture is greater than 300 parts per million (ppm), BAD things are happening in your lube system. If you have ever worried about moisture levels in your lubrication oil, you are rightly co

Aug 19, 20241 min read

OFS Supports ALL Of Your Oil & Fuel Purification Needs

At Oil Filtration Systems, we enable end-users to achieve optimal fluid cleanliness in their critical lubrication, hydraulic, and fuel oil systems by manufacturing and supplying Oil Purification Equipment designed to remove contamination (water, particulate, varnish, etc.) from a wide variety of hydraulic, lubrication, and fuel oils. When used in conjunction with our high-efficiency filter elements rated Beta(c)>1000 in a variety of micron sizes, our systems will enable you t

Aug 13, 20242 min read

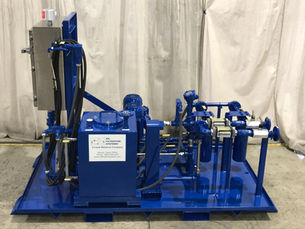

Bearing Lube Oil Systems provide the life blood to many bearings, gearboxes, and/or blowers – Lubrication Oil

Bearing Lube Oil Systems (also known as Circulating Oil Systems or Lube Oil Skids) are an integral and very important part of most rotating equipment used in many industrial applications around the world. Whether part of the rotating equipment itself or a separate stand-alone system designed by a third party, a Bearing Lube Oil System provides the life blood to many bearings, gearboxes, and/or blowers – Lubrication Oil. Each application for a Bearing Lube Oil System is unique

Jul 15, 20242 min read

Maximize your turnaround impact and success

Ensure that the hydraulic/lube oil systems in your critical rotating equipment are absolutely clean and dry for start up! We at OFS are uniquely positioned to help support all of your hydraulic/lube oil flushing and filtration needs. Whether you manage and self-perform your own oil flushing and filtration work in house, or if you prefer complete turn-key service, you can get the equipment and services you need from OFS. We have a vast fleet of more than 200 filtration/flushin

Jul 9, 20241 min read

Perform internal tank cleanouts (if possible) - Tip #2

This weeks #FuelCleanlinessTip is perform internal tank cleanouts (if possible). Vacuum out residual fuel and sludge off bottom with shop-vac Wipe down all surfaces with lint-free rags Remove surface rust with cleaning agent Sometimes, the problem is the tank itself (not just the fuel). In severe cases, microbial growth remains on the tank floor and walls, re-contaminating new fuel upon delivery. If algae has been a recurring problem, spraying down the inside of the tank w

Jul 2, 20241 min read

What you can do to ensure that your fuel is absolutely clean and dry - Tip #1

Happy #FuelCleanlinessTipTuesday ! DID YOU KNOW? Water contamination in fuel causes a myriad of problems. Water acts as a catalyst for fuel degradation over time, causing the formation of sludge. Water also enables microbial growth within the fuel as well as promotes corrosion within fuel injectors. Water in fuel even causes inefficient combustion and engine performance. The question becomes, "Where does particulate and water contamination in fuel tanks come from?" Simply: •

Jun 25, 20241 min read

Maximize the Profitability of Your On-Site Filtration Systems - Upgrades & Refurbs

DID YOU KNOW? We want to help you maximize the reliability and performance of your existing oil purification equipment. We repair, rebuild, service, and upgrade all brands of Vacuum Dehydrators, both new and old. We can refurbish your old VDOPS with new components and make it “like new” for a fraction of the cost of a new unit. We offer many upgraded features to make your existing Vacuum Dehydrator more reliable, more versatile, more effective, and less costly to operate. We

Jun 3, 20241 min read

Filtration Solutions for Fyrquel Phosphate Ester Fluid and Other Fire Resistant Fluids

THE QUESTION We often get asked, "Does your Vacuum Dehydrator work on fire resistant hydraulic oils like Fyrquel®?" THE OIL FILTRATION SYSTEMS SOLUTION Yes it does, and with only a few minor modifications, our standard design is fully compatible for long-term dedicated use with phosphate ester and other synthetic fluids. Just like mineral-based and synthetic hydraulic and lubrication oils, it is very important to keep Fyrquel® and other fire resistant fluids absolutely clean

May 6, 20242 min read

On-Site Turn-Key Fuel Filtration & Coalescing Services

OFS has experienced and highly trained Field Service Technicians who have been performing Turn-Key Fuel Filtration & Coalescing services at customers’ facilities for over 20 years. Whether you have a Standby Diesel Generator with 500-gallons of dirty, wet diesel fuel, or you have a large 100,000 gallon Bulk Fuel Tank with biological growth in it, we have the equipment and manpower needed to get the job done quickly and efficiently. With a large fleet of specialized fuel filtr

Apr 17, 20241 min read

Leave Your Lube Oil Cleanliness to Oil Filtration Systems

NO MANPOWER? WE GOT YOU COVERED. LEAVE YOUR LUBE OIL CLEANLINESS TO OIL FILTRATION SYSTEMS! Turnarounds are often the perfect time to perform much needed maintenance on the lube oil systems of critical hydraulic and rotating equipment. While systems are scheduled to be down and offline for several days, hydraulic and lube oil reservoirs can be drained, and experienced crews can then perform confined space entry tank clean-outs. At the same time, the oil can be thoroughly fil

Apr 2, 20242 min read

bottom of page