What Is A Bearing Lube Oil System?

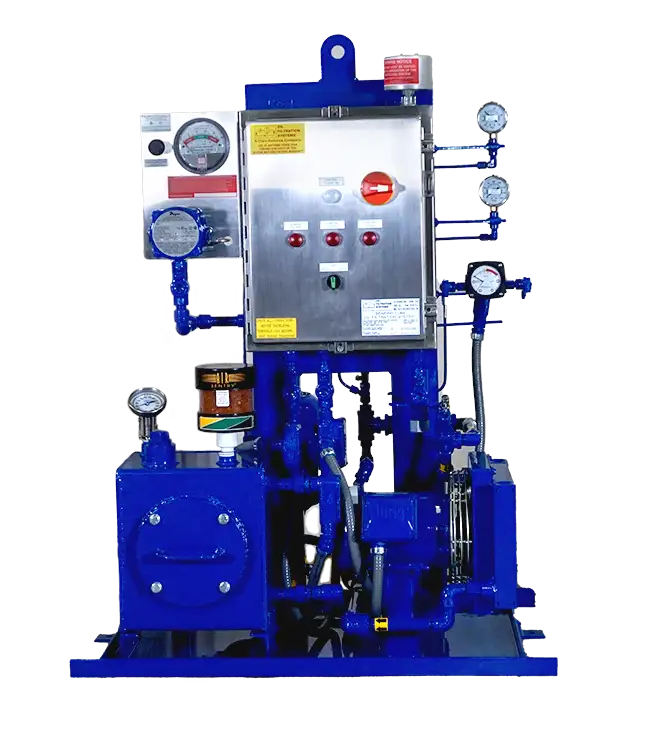

A Bearing Lube Oil System is a custom-designed skid built to deliver clean filtered lube oil to bearings at a specified flow rate, pressure, and temperature. Essential for optimal performance and reliability of critical rotating equipment across a wide range of industries, they typically include the following features:

-

Redundant positive displacement gear pumps - one in operation, one on standby

-

Both high-pressure and low-pressure circuits (if necessary)

-

Duplex filter housings – allow for the change-out of a plugged filter element without interrupting the flow of oil

-

High-efficiency pleated microglass filter elements rated Beta>1000 per ISO 16889 – ensure oil cleanliness that meets or exceeds stringent OEM specifications

-

Air-cooled or water-cooled heat exchanger (oil cooler) – maintain cool bearing temperatures

-

Flow divider(s) and flow meter(s) - ensure proper flow rate of oil to each bearing

-

Lube oil reservoir – equipped with low watt-density immersion heater for cold start-up, desiccant air breather, level sight glass, and high/low level float switches

-

NEMA 4 electric control panel with remote diagnostic capability – controls and alarm indicators can be integrated with the customer’s DCS.

Bearing Lube Oil System Is Ideal For:

-

Mining industry – large crushers and mills (ISO 320 gear oil)

-

Cement industry – large crushers and mills (ISO 320 gear oil)

-

Pulp & Paper – paper machines (ISO 220 paper machine oil)

Technical Specifications

Contact Us

Product Overview

Standard Features

-

All vessels built to ASME code design (section VIII, division I)

-

Differential pressure gauges give a positive indication when filter elements are plugged and need to be changed

-

Upstream & downstream fuel sample ports

-

Duplex configurations that enable an operator to change out plugged filters without interrupting the flow of oil through the filters

Optional Features

-

ASME code (U) stamp

-

Electric differential pressure switches for remote monitoring

-

IECEX electrical components (class 1, division 1 or class 1, division 2)

-

Stainless steel materials of construction