top of page

News & Insights

Explore our articles to discover how our innovative solutions can help you improve efficiency, reduce costs, and protect your valuable equipment.

News & Insights

Explore our articles to discover how our innovative solutions can help you improve efficiency, reduce costs, and protect your valuable equipment.

Aircraft Tooling Company Extends Life of Cutting Fluid, Prevents Downtime, and Saves Over $45k By Installing Custom Oil Filtration System

The customer is a prominent machine tool manufacturer located in Millersburg, Pennsylvania. The company specializes in producing high-quality cutting tools for metal removal applications in the aircraft manufacturing industry, where precision and quality standards are non-negotiable. The Challenge: Particulate Contamination in Centralized Coolant System They operate a 1,400-gallon centralized cutting fluid reservoir that distributes coolant to multiple machining stations

Jan 72 min read

Case Study: Steel Forging Press Extends Equipment and Oil Life By Implementing 50 GPM VDOPS – Prevents Downtime and Saves over $70,000 in Operating Costs

A leading steel forging manufacturer that produces high-tensile components for government applications was facing ongoing maintenance issues with one of its largest forging presses. The plant operates a 5,000-ton forging press powered by a 5,000-gallon hydraulic reservoir using biodegradable fire-resistant oil (Fuchs Renosafe 46) to ensure workplace safety and environmental compliance. The Challenge: Elevated Water and Particulate Contamination The customer began experienci

Dec 23, 20252 min read

Aluminum Extruder Reclaims Used Hydraulic Oil From Leaking Presses – Saves $450,000 In One Year

New oil purchased for regular consumption which is now being cleaned through a 50 GPM Vacuum Dehydration Oil Purification System. Hydraulic Oil Contamination Challenges in Aluminum Extrusion Manufacturing A national leader in the manufacturing of extruded aluminum products in Texas was facing a costly and persistent challenge: hydraulic leaks in four large horizontal aluminum extrusion presses. Each press relies on complex hydraulic systems with high-value pumps and precision

Dec 16, 20252 min read

Varnish Contamination In Large Hydraulic Shear

To effectively mitigate the varnish contamination in the hydraulic oil, the plant decided to implement a 10 GPM Varnish Removal System.

Oct 17, 20251 min read

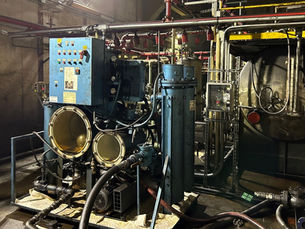

Large Hydraulic Press – Particulate & Water Contamination

Problem: An aging steel facility was facing major operational challenges, including hydraulic oil leaks, groundwater seepage into the reservoir, and frequent pump failures, which were costly and disruptive to operations. The Oil Filtration Systems Solution: A multi-stage filtration system was implemented, including pre-filtration for particulates (an OFS Multi-Bag Filter Housing Assembly), pre-filtration for free water (an OFS Lube Oil Coalescer Housing Assembly), and continu

Apr 17, 20251 min read

OFS - Your Trusted Partner for Equipment, Rentals & Services

Need Oil Filtration Support? We’re Ready to Help How OFS Can Support YOU : 1. Equipment Sales Vacuum dehydrators, varnish removal systems, filtration skids, and more—all built in Boerne, TX for fast support. 2. Equipment Rentals Over 250 rental units, including 80 dehydrators and 45 flushing skids. Rapid response—same-day shipping for urgent needs. 3. Field Services High-velocity oil flushing for outages and new piping installations Reservoir cleanouts Fluid and diesel fuel f

Apr 3, 20251 min read

Reduce Downtime & Save Costs – Rent Oil Purification Equipment

Why Buy When You Can Rent? Keep Your Operations Running Smoothly Tired of oil contamination issues causing costly downtime? Stop throwing away perfectly good oil due to particulate, water, & varnish contamination. With Oil Filtration Systems' rental equipment, you get a cost-effective, maintenance-friendly solution to keep your operations efficient. We have the largest, newest, and best-maintained fleet of rental Oil Purification Equipment in stock for scheduled and emergen

Mar 27, 20251 min read

Customer Testimonial - Kimbro OilEP-800 Recycling Results

The Problem: A metal processing facility experienced a failure in one of the components on a large Central Gear Oil System. This failure severely contaminated their 4,500-gallon custom blend EP-800 Gear Lubricant System with metal particulate. The oil was in pristine condition but needed to have the mass amounts of metal fines removed. The viscous nature (800 CST at 40 C) of the oil posed a challenge for efficiently removing this particulate. The Solution: "After conversation

Mar 18, 20251 min read

Extend the Life of Hydraulic Oil: Solutions Beyond Disposal

Why throw away perfectly good hydraulic oil just because it's dirty? Older hydraulic units often develop leaks which put used oil on the floor or in a pit within the plant. This used oil is typically loaded with particulate and water contamination, and end users often dispose of it and replace it with new. Disposal of used oil and purchase of new can be very costly, but there is a better solution. Reclaim Used Hydraulic Oil with a Vacuum Dehydration Oil Purification System

Jan 13, 20251 min read

We’re your go-to partner for all your oil and fuel purification needs!

DID YOU KNOW? We’re your go-to partner for all your oil and fuel purification needs! Since 1999, Oil Filtration Systems® has been a leader in manufacturing custom oil and fuel purification equipment. We specialize in tailored solutions to meet your unique requirements—offering custom sizes and configurations with various options such as inline digital particle monitors, moisture sensors, and complete data-gathering packages. We can help you achieve MORE: ✅ Extend the life of

Dec 26, 20241 min read

Optimize the reliability and performance of your Vacuum Dehydration System

Check out our latest webinar: Extending the Life of Your Vacuum Dehydration Oil Purification System - Preventative Maintenance. Key Takeaways: 1) extend the life of critical components (vacuum pump, etc.) 2) preventative maintenance steps and procedures 3) recommendations for optimal water extraction performance and results 4) recommendations for proper filter element selection Watch the video here: Email info@oilfiltrationsystems.com to discuss your specific application n

Oct 16, 20241 min read

High Viscosity Oil Filtration

Effective kidney-loop filtration of high viscosity gear oils can be very challenging, especially at cooler ambient temperatures. Proper sizing of the pump/motor and filter elements for optimal filtration performance is always important, but it takes on even more significance with high viscosity gear oil (ISO VG 220 – ISO VG 680). The first challenge for a kidney-loop filtration system on high viscosity gear oil is proper pump/motor selection. Most off-the-shelf filter cart

Mar 4, 20242 min read

Maximize the profitability of your on-site filtration systems with Oil Filtration Systems

We have one of our 50 GPM Vacuum Dehydrator and Filtration Systems installed on ISO 460 lube oil at a Steel Mill in Kentucky. FUN FACT: this OFS dehydrator/filter system has been in operation since 2007! The steel mill cannot operate the hot strip mill without the OFS dehydrator. The Facility Engineer at the plant wanted to ensure another 15+ years of use from this unit. In order to do so, this system will be sent back to our facility for rebuild. We will then supply the mill

Feb 16, 20231 min read

Extremely high particulate contamination source and remedy at a roll mill

Problem Untreated high levels of particulate contamination have resulted in the costly remedy of emptying a 2500 gallon reservoir and replacing the Meropa 460 gear oil. The system includes a high flow, low pressure pump delivering gear oil to four main gearboxes in the roll mill with only a single pressure filter. The return flow exceeds 600 gallons per minute intermittently, and there is no return filtration or a kidney-loop system. The worst ISO cleanliness code came back a

Dec 19, 20222 min read

bottom of page