Varnish Contamination In Large Hydraulic Shear

- Kristen Modzelewski

- Oct 17, 2025

- 1 min read

Updated: Oct 30, 2025

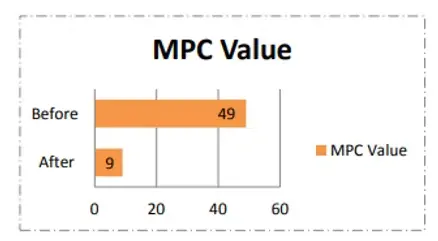

Problem: Operators of a large Hydraulic Shear noticed elevated temperatures and a discoloration of the oil in their 2,500-gallon hydraulic oil system. This prompted them to conduct oil analysis, and the lab results revealed an elevated varnish potential number of MPC 49. If left untreated, the operators were worried that varnish would eventually cause premature failure of the large Hydraulic Shear, requiring costly repairs and downtime.

Solution: To effectively mitigate the varnish contamination in the hydraulic oil, the plant decided to implement a 10 GPM Varnish Removal System utilizing Granular Adsorbent Media and High Efficiency Beta>1000 Filter Elements to re-circulate the reservoir in a kidney-loop configuration, continuously removing impurities as the hydraulics of the Shear were actuated.

Results: The starting varnish content in the oil was MPC 49. After approximately 6 weeks of run-time, the varnish potential dropped significantly to MPC 9. By implementing a Varnish Removal System from Oil Filtration Systems, and maintaining the oil of a large Hydraulic Shear at or below the recommended varnish potential of MPC 10, operators at this large Steel Mill did everything possible to ensure optimal reliability and operation/performance of the Hydraulic Shear, while minimizing downtime and costly repairs.

Comments